If “diamonds are a girl’s best friend” and “clothes make the man,” does “copper complete the cook?” Probably not, but it can make cooking easier. Since the time I carried a copper pot home from Paris in my briefcase and used it for the first time, I’ve been convinced that for many things, copper provides the best material for cookware.

Different cooking methods are accomplished using different types of pots and pans over various heat sources. How the chef wants to change the structure of food, i.e., cook, should dictate the choice of heat sources and implements — not the opposite. But, most of us are limited in the types of heat sources and so we have to adjust our needs and results accordingly. In my kitchen, the source of energy is electricity and I have two means to impart the heat produced by electricity into food — a cook top and an oven.

The electric cook top I use has the traditional coils that heat by resistance. Once hot, they pass heat to the cooking pot primarily by means of conduction. There is also some heating by radiation since neither the bottom of the pots or the burners are perfectly flat. Assuming the primary heating means is conduction, I need pots that can safely be placed in contact with a burner. Although I have made use of glass and ceramic, including Chinese sand pots, on electric burners, for everyday use metal is certainly best.

Once it is determined how the heat is transferred into the pot, i.e., from an electric burner, the cook also has to decide how the heat will be transferred to the food being cooked. Blanching, boiling, and deep-frying usually require a vessel with depth, such as a saucepan. Sautéing or shallow frying is usually done in a shallow vessel so that moisture released from the food is easily evaporated. A sauté pan or fry pan is usually used for this function.

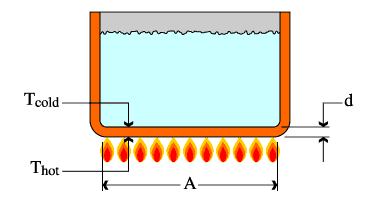

The last part of the cooking equation that needs to be considered is how the heat gets from the outside of the vessel to the inside. Heat transfers through different metals at different rates. The common metals used in pots — copper, aluminum, stainless steel, iron, steel — all have different rates of heat transfer. The quickest (best?) heat transfer is through copper. The rate of transfer decreases in speed with aluminum being the next fastest and the iron-based metals the slowest. The rate of transfer is also a function of material thickness. As logic would dictate, the thinner the material, the faster heat will transfer through it. But if too thin, there will be hot spots produced by the uneven application of heat by the burner. The ideal vessel combines a thick enough wall with a fast enough heat transfer to cook evenly and with appropriate speed.

If a pot made of thin metal is placed on an electric burner, the temperature of the metal will mimic the shape of the burner. These “hot spots” will cause food to burn in some areas and undercook in others. A thick-bottom pot will cook more evenly.

Typical saucepan,

casserole in French

Typical sauté pan,

plat à sauter in French

My personal preference for saucepans and sauté pans up to 6-quart capacity is thick copper with a stainless steel inner surface, or cladding. The copper should be at least 2 mm thick to prevent hot spots. The stainless steel cladding allows for easier browning, deglazing, and cleaning. The handles are made of iron because of iron’s low heat transfer rate and its ability to withstand high oven temperatures. For larger capacities, such as stock pots, I prefer stainless steel pans with a thick (at least 6 mm) aluminum base for even, albeit slower, heat transfer. (Stock is cooked over low heat for long periods of time so even heat transfer is more important than speed.) In the larger sizes, I also prefer the stainless because the copper is just too heavy.

Copper pots from France are generally available in two varieties: a cooking version, as described above, and a table service version made of thinner copper with brass handles. The table service version is designed for presenting, or serving, a dish at the table. The dish is usually cooked in a different pot and just served in this type of vessel. Both types can be obtained with a tin-lined inner surface instead of the stainless. This is an older method of coating the cooking surface, is not as sturdy as stainless, and periodically has to be reapplied.

Saucepans with copper coatings on the outside provide little of the benefit of real copper pots. Stainless steel pots with aluminum cores are also poor substitutes.

One of the most common complaints I hear about copper pots is that they are too expensive and that they have to be polished. Polishing is strictly a matter of aesthetics, not function. I personally find the patina of aged copper attractive, so I don’t worry about polishing my pots.

As to expense, when purchased by fax, or on the internet, from France the price is often less expensive than All-Clad or Calphalon pots with poorer heat transfer capabilities. Note: the copper pots available for sale in the United States are more expensive and tend to be table service pots, not professional weight pots.

(By the way, for frying, I prefer cheap, professional-grade, Teflon-coated aluminum fry pans. The metal handles allow for them to be placed in the oven as well as on the cook top. When they wear out I throw them away and buy more at my local restaurant supply house.)

(By the way, for frying, I prefer cheap, professional-grade, Teflon-coated aluminum fry pans. The metal handles allow for them to be placed in the oven as well as on the cook top. When they wear out I throw them away and buy more at my local restaurant supply house.)

©2001, 2014 Peter Hertzmann. All rights reserved.